-

This is a continous press, that uses no cheesecloths. It compresses the produce by use of a stainless steel screw traveling through a perforated tube. You simply put the produce in one end, the juice comes out of a pipe on the bottom, and the dried pulp or waste comes out the other end continuously. Model 100 Specifications:

This is a continous press, that uses no cheesecloths. It compresses the produce by use of a stainless steel screw traveling through a perforated tube. You simply put the produce in one end, the juice comes out of a pipe on the bottom, and the dried pulp or waste comes out the other end continuously. Model 100 Specifications:- Capacity: .5 ton/hour

- Power: 1.1KW

- Size: 940×320×820MM

- Juice Rate: 65-68%

- Sieve: 0.6MM

- Weight: 110kg.

- UL certified motors

-

The Stage III screw press is built for large production. Can be designed within a whole system, including trimming tables, automatic wash, incline conveyor feeding the built-in heavy duty mill and into the press. This system can also be installed on a skid, so it could be transported to different production plants when the seasons change and growing areas change. Model 300 Specifications:

The Stage III screw press is built for large production. Can be designed within a whole system, including trimming tables, automatic wash, incline conveyor feeding the built-in heavy duty mill and into the press. This system can also be installed on a skid, so it could be transported to different production plants when the seasons change and growing areas change. Model 300 Specifications:- Capacity: 2.5 tons/hour

- Power: 11KW

- Size: 2020×640×1560MM

- Juice Rate: 68-72%

- Sieve: 0.6MM

- Weight: 400kg.

-

The Model 75 is our smallest juice press with an integrated shredder system, but it comes complete with all of our STANDARD full-size features (see the list below). Two inches narrower than the Model 100, the Model 75 was designed to accommodate customers with space restraints, yet still maintain an adequate production volume. Like the slightly larger Model 100, it is perfect for Juice Bars, Health-food Stores, Storefront Operations,low volume Juice Bottling, and more. Model 75 Specifications:

The Model 75 is our smallest juice press with an integrated shredder system, but it comes complete with all of our STANDARD full-size features (see the list below). Two inches narrower than the Model 100, the Model 75 was designed to accommodate customers with space restraints, yet still maintain an adequate production volume. Like the slightly larger Model 100, it is perfect for Juice Bars, Health-food Stores, Storefront Operations,low volume Juice Bottling, and more. Model 75 Specifications:- Juice Rate: 10-30 Gallons per Hour (37-75 Liters per Hour)

- Electrical: 20A, 200-240VAC, 1ɸ (Single Phase)

- L6-20P Plug and Cord

- 9" Shredder Blade(s)

- Shredder Speed: 0-3600 RPM

- Net Weight: 445lb (209kg)

- All Stainless Steel and Electropolished Construction

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- No Feed Tube/No Shredding

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- Shredder System w/Interlock

- Juice Collection Pan(s)

- Two (2) Press Bags (Model 200: 4)

- Perforated Press Board(s)

- Three (3) Shredder Blade Sizes

- Produce Plunger

- Tool Set w/ Spare hardware

- Limited Warranty

-

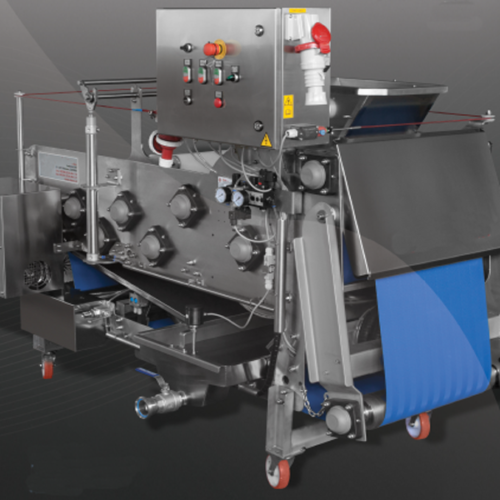

The Model 200 is our starter unit for the next step up. Two press zones and a moveable Shredder System act together to greatly increase juice production. Produces as much juice as competing 6 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and high-volume operations. Specifications: Juice Rate: 40-100Gallons per Hour* (150-370 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 770lb (350kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:

The Model 200 is our starter unit for the next step up. Two press zones and a moveable Shredder System act together to greatly increase juice production. Produces as much juice as competing 6 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and high-volume operations. Specifications: Juice Rate: 40-100Gallons per Hour* (150-370 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 770lb (350kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:- All Stainless Steel and Electropolished Construction

- Stainless Hardware and Lines

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- No Feed Tube/No Shredding

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- Shredder System w/Interlock

- Juice Collection Pan(s)

- Two (2) Press Bags

- Perforated Press Board(s)

- Three (3) Shredder Blade Sizes

- Produce Plunger

- Tool Set w/ Spare hardware

- Limited Warranty

-

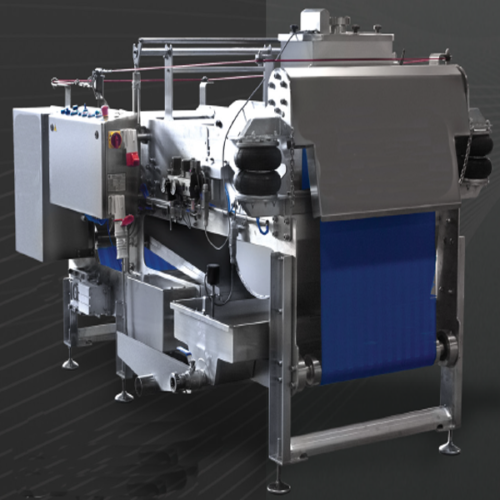

The Model 400 is the ultimate commercial juice press. Two press zones - each section pressed independently - provides a continuous juicing cycle. One section can be pressed while the other is filled with shredded produce. Double bags per zone (four bags total) makes high volume juice/cider production a snap. Our patented "wave" boards help this machine produce as much juice as competing 8-12 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and other high-volume commercial operations. Specifications: Juice Rate: 60-240Gallons per Hour* (227-900 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 1100lb (500kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:

The Model 400 is the ultimate commercial juice press. Two press zones - each section pressed independently - provides a continuous juicing cycle. One section can be pressed while the other is filled with shredded produce. Double bags per zone (four bags total) makes high volume juice/cider production a snap. Our patented "wave" boards help this machine produce as much juice as competing 8-12 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and other high-volume commercial operations. Specifications: Juice Rate: 60-240Gallons per Hour* (227-900 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 1100lb (500kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:- All Stainless Steel and Electropolished Construction

- Stainless Hardware and Lines

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- No Feed Tube/No Shredding

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- Shredder System w/Interlock

- Juice Collection Pan(s)

- Four (4) Press Bags

- Patented Wave Press Board(s)

- Three (3) Shredder Blade Sizes

- Produce Plunger

- Tool Set w/ Spare hardware

- Limited Warranty

-

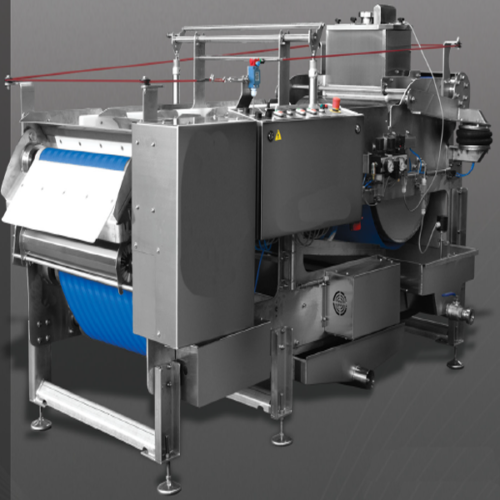

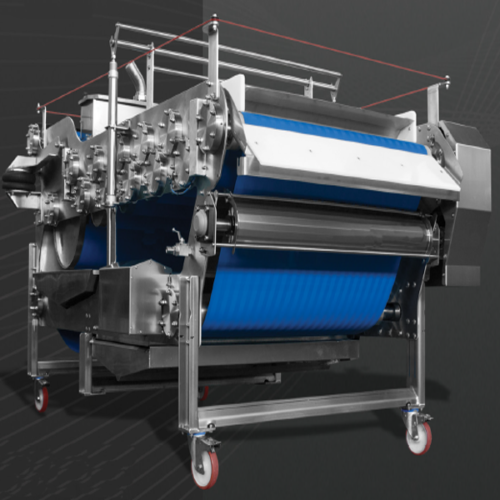

Designed for industrial use, the Model 800 is small enough to be maneuvered around your facility, but powerful enough to produce 120-480 gallons of juice per hour. Flexibility is key to producing multiple juice blends in high volumes. Large, fixed position (in-place), multi-layer presses generate high liquid volumes, but are too cumbersome to change over for different products. A team of Model 800 Industrial Juice Presses can give your operation the ability to adapt to changing production requirements, and at a fraction of the cost! The Model 800 all-stainless hydraulic press accommodates eight press bags, each flanked by our patented heavy-duty “wave” boards for maximum juice extraction. Juice is collected in a specially designed 24 gallon pan with a stainless sanitary valve and discharge allowing easy transfer of juice to a bucket (provided) or sanitary pumping system for central collection. Press bags and boards are actuated by two heavy duty, all-stainless, hydraulic cylinders. The simple and clean cartridge-style design allows the entire 8-layer press zone to be rotated for pomace/cake removal. A pomace/cake collection bin is provided to make waste removal simple and efficient. No hassle, no mess, safe operation, and no need to remove press bags between press cycles. The Model 800 is made to the same exacting standards as our commercial presses and includes all of our standard features: Meets or exceeds all FDA, USDA, and NSF food safety standards! Specifications: Juice Rate: 120-480 Gallons per Hour* (450-1800 Liters/Hr) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord Net Weight: ~3000lb (1400kg) *Depends greatly on produce. Model 800 Standard Feature List:

Designed for industrial use, the Model 800 is small enough to be maneuvered around your facility, but powerful enough to produce 120-480 gallons of juice per hour. Flexibility is key to producing multiple juice blends in high volumes. Large, fixed position (in-place), multi-layer presses generate high liquid volumes, but are too cumbersome to change over for different products. A team of Model 800 Industrial Juice Presses can give your operation the ability to adapt to changing production requirements, and at a fraction of the cost! The Model 800 all-stainless hydraulic press accommodates eight press bags, each flanked by our patented heavy-duty “wave” boards for maximum juice extraction. Juice is collected in a specially designed 24 gallon pan with a stainless sanitary valve and discharge allowing easy transfer of juice to a bucket (provided) or sanitary pumping system for central collection. Press bags and boards are actuated by two heavy duty, all-stainless, hydraulic cylinders. The simple and clean cartridge-style design allows the entire 8-layer press zone to be rotated for pomace/cake removal. A pomace/cake collection bin is provided to make waste removal simple and efficient. No hassle, no mess, safe operation, and no need to remove press bags between press cycles. The Model 800 is made to the same exacting standards as our commercial presses and includes all of our standard features: Meets or exceeds all FDA, USDA, and NSF food safety standards! Specifications: Juice Rate: 120-480 Gallons per Hour* (450-1800 Liters/Hr) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord Net Weight: ~3000lb (1400kg) *Depends greatly on produce. Model 800 Standard Feature List:- Sanitary Features:

- All Stainless Steel and Electropolished Construction

- Stainless Hardware and Lines

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- 24 Gal. Juice Collection Pan with Sanitary Fittings/Valve

- Eight (8) Press Bags

- Patented Wave Press Board(s)

- Tool Set w/ Spare hardware

- Limited Warranty

-

100-500 Liter Tank Specifications:

100-500 Liter Tank Specifications:- Material: All of the contact parts are made of SS316 stainless, the rest 304 stainless

- Size: 100-500 Liters

- Agitation: Scrape Agitation

- Power: 220V/60HZ/3 Phase UL certified motors included

- Motor Covers: Stainless

- Piping: Stainless Steel Piping, valves, and fittings included, when system is ordered

-

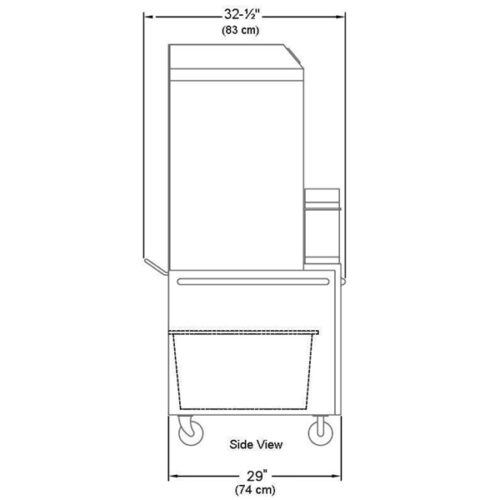

Model Multi-Fruit Juicer Specifications:

Model Multi-Fruit Juicer Specifications:- Throughput: 20 fruit per minute

- Fruit Hopper Capacity: 40 lbs. (18 kg) – 1 carton

- Processing Speed: 80-120 quarts (76-114 liters) per hour

- Reservoir Capacity: 3-1/2 gallons (13 liters)

- Height: 67" (170 cm)

- Width 27" (69 cm)

- Depth 32" (81 cm)

- Height: 73" (186 cm)

- Width 30" (76 cm)

- Depth 36" (91 cm)

- 115 volts

- 60 Hz

- 20 amps service

- Single phase

- 110/220 volts...

- 50/60 Hz

- 20/10 amps service...

- single phase

- Completely enclosed, safety interlock switches

- Finish High impact, flame retardant ABS or stainless steel (optional)

- Weight: 535 lbs. (243 kg)...

- Shipping Wt.: 570 lbs. (259 kg)

- Waste Container Holds: 40 lbs. (18 kg)

- Average Fruit Size: 2-1/2" (63.5 mm) to 3-7/8" (98 mm)

- Orange Count: Per 40 lb. (18 kg) Carton...48 to 138

- Grapefruit Count: Per 40 lb. (18 kg) Carton...48 to 56

- Lemons, Limes Count: Per 40 lb. (18 kg) Carton...95 to 200

- Versatility: Juices all types of citrus fruit without adjustment

- Optional: Strainer tubes for various juice pulp requirements

- High quality juice with minimal peel oil

- Reliable, easy to operate and safe equipment that processes a wide range of types and sizes of citrus

- fruits

- A juicer that achieves the highest juice yields from all fruits – at a reasonable speed

- Sweet tasting, freshly squeezed juice

- made daily

- Good value for the price

- Nothing but juice – no seeds, no peel

- To see the juicing process in action

- A sanitary design to ensure product quality and shelf life

-

The Z450 and Z450P models have been designed to obtain top quality fresh juices from whole fruits from the most unique technology available. The machine is able to squeeze all types of citric fruit- oranges, lemon, limes, tangerines and grapefruits as well as the Z450P being able to process pomegranates on top of the citric capabilities. The juice extractor is pre-assembled and factory tested before delivery for quick and easy installation. Model Z-450 Specifications: Juicing Kit (standard): 8 cavity intermediate Kit Production: 400¸450 litres/hour Diameter of Fruit: Min. Ø70 mm; max. Ø85 mm Optional - 7 Cavity : min. Ø85 mm; max. Ø100 mm - 9 Cavity : min. Ø60 mm; max. Ø70 mm Weight: 400 Kg (approximate) Measurements (h x l x w): 2.2 x 2.5 x 1 (metres) Consumption: 2,01 kW Voltage: 220V / 60 Hz.

The Z450 and Z450P models have been designed to obtain top quality fresh juices from whole fruits from the most unique technology available. The machine is able to squeeze all types of citric fruit- oranges, lemon, limes, tangerines and grapefruits as well as the Z450P being able to process pomegranates on top of the citric capabilities. The juice extractor is pre-assembled and factory tested before delivery for quick and easy installation. Model Z-450 Specifications: Juicing Kit (standard): 8 cavity intermediate Kit Production: 400¸450 litres/hour Diameter of Fruit: Min. Ø70 mm; max. Ø85 mm Optional - 7 Cavity : min. Ø85 mm; max. Ø100 mm - 9 Cavity : min. Ø60 mm; max. Ø70 mm Weight: 400 Kg (approximate) Measurements (h x l x w): 2.2 x 2.5 x 1 (metres) Consumption: 2,01 kW Voltage: 220V / 60 Hz. -

Model PGE Specifications:

Model PGE Specifications:- Production: 500 Fruits/min.

- Yield: from 48% to 52% (according to variety of fruit).

- Approximate weight: 1.700 kgs.

- Consumption: 15.5 Kw/hour.

- Voltage: Three-phase 220V / 50-60 Hz. // 380V / 50-60 Hz.

- Water: 5.28 - 6.6 Gal/min to 4 bar (316.8 - 396 Gal/hour to 59º F).

- Air compressed: For instrumentation to 6 bar.

-

The Stage II semi-automatic overflow filler is a logical next step for a medium size cold press juice facility. You can chose from 4, all the way up to 8 heads filling juice at one time. It is ideal for a fast-growing company to bottle their juices at an economical price. Model Specifications:

The Stage II semi-automatic overflow filler is a logical next step for a medium size cold press juice facility. You can chose from 4, all the way up to 8 heads filling juice at one time. It is ideal for a fast-growing company to bottle their juices at an economical price. Model Specifications:- Simple Design

- 4 to 8 Liquid Filling Nozzles

- 316 Stainless Steel Contact Parts are Standard

- Heavy-duty 2 inch bore air cylinder with mechanical stroke adjustment

- 5.5 Gallon stainless steel overflow tank

- 4 ports hose 304 stainless steel feeding manifold

- Fill Glass, Tin, Plastic Containers

- All contact parts are stainless steel, sanitary, Teflon, Viton, Buna, and hoses per your requirements

- Calibrated guide for fast height changeovers

- Leveling of the machine by 16mm 304 stainless steel leveling screws

- 13 Gallons per minute diaphragm pump

- Height nozzles can be fully adjustable

- Container height adjustment from 1.5 to 12 inches high

- No change parts needed for various types of containers

- Air filter regulator and safety lockout valve included

- 10 cfm@80psi

-

The Stage III automatic in-line overflow filler is for companies that are doing a larger production, wanting to cut labor costs and at a very economical price. It is ideal for a larger commissary or juice plant, as it can fill different varieties of bottles quickly. Model A-12 Specifications:

The Stage III automatic in-line overflow filler is for companies that are doing a larger production, wanting to cut labor costs and at a very economical price. It is ideal for a larger commissary or juice plant, as it can fill different varieties of bottles quickly. Model A-12 Specifications:- All Stainless Steel Frame

- Stainless Steel Conveyor, 12 Ft. or Longer with Adjustable Guide Rails

- Electronic/Pneumatic Timing and Counting System

- Drip Tray

- EZ Clean Manifold

- Handle From 1/2 Pint To One Gallon Containers

- Air Cylinders, Bottle Gates, Sensors & Timers Control All Movements

- Stainless Steel Centrifugal Pump

- Totally Enclosed Motor with Variable Speed Drives

- Solid State PLC Control with Color Touch Screen

- 316 Stainless Steel Contact Parts Are Standard

- Nema 4x Enclosures

-

The Stage I Model TM Applicator enables the user to label all kinds of cylindrical objects by simply inserting the container and pressing a foot switch. Once the foot switch is activated the label is applied at over 4.5″ per second, most water bottles are labeled in less than 2 seconds! This allows the user to quickly remove the bottle and insert another to start the procedure again. Once a rhythm is established bottles are labeled VERY quickly. The Stage I can label products at speeds of 1200 Pieces an hour! Model TM Specifications:

The Stage I Model TM Applicator enables the user to label all kinds of cylindrical objects by simply inserting the container and pressing a foot switch. Once the foot switch is activated the label is applied at over 4.5″ per second, most water bottles are labeled in less than 2 seconds! This allows the user to quickly remove the bottle and insert another to start the procedure again. Once a rhythm is established bottles are labeled VERY quickly. The Stage I can label products at speeds of 1200 Pieces an hour! Model TM Specifications:- DON’T BE FOOLED! Know you're getting the REAL DEAL with Bottle-Matic, we designed the machine from the ground up! (Not imported, or knock-off)

- SATISFACTION GUARANTEED. If we cannot make you happy within 21 days, send it back.

- Label objects from .5″ to 10″ diameter. From a Test Tube to a 1.5 gallon bottle.

- ACCURATE: Holds 1/64th” side-side accuracy on most containers.

- Label cylinders to 15″ length (or longer if the item has a neck).

- Able to handle most tapered containers by simply adjusting the idle roller position.

- Labels over 1000 pcs per hour with average dexterity. (More if you have a fast employee).

- Side frames: Laser-Cut from the drawing quality steel then formed, countersunk, de burred, and inspected one at a time at our facility.

- Dispensing Tables: formed out of 6061-T6 Aluminum. The peel edge is hand milled to spec within .001″ using a special hand-made cutting tool to get that perfect peeling edge needed to dispense labels without tearing the backing paper (35 years of perfecting the peeling action).

- Dispensing tables are POLISHED with ultra-fine polishing compound so paper flows freely around the plate.

- Stage I uses DUAL AC shaded pole gear motors, made in the USA, to our specifications (no cheap DC motors here).

- While others copy our technology and designs, we continue to be in the forefront bottle label applicator design.

- Costs are a fraction of similar machines of the same build quality.

- Micro-Switch activated, will work on all kinds of labels.

- We are able to do any modifications necessary for those hard to label containers, but labels most containers without modification.

-

Portable design The Stage II can be moved easily, so you can set up exactly where you’d like. It can be positioned on a tabletop or bench, or moved in-line for automatic or semi-automatic applications – a convenience not found with heavier, more elaborate labeling machines. Simple to use With our advanced sensors, the Stage II delivers optimal efficiency. Hand wheels provide simple adjustments, enable quick set-up and easy changeover. Easy to maintain In strict compliance with Good Manufacturing Practices (GMP) standards the Stage II is made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments. Additionally, its simplistic design enables quick fixes and easy adjustments. Given this durability and easy maintenance, the Stage II affords you a solid choice in labeling machine longevity. Flexibility

Portable design The Stage II can be moved easily, so you can set up exactly where you’d like. It can be positioned on a tabletop or bench, or moved in-line for automatic or semi-automatic applications – a convenience not found with heavier, more elaborate labeling machines. Simple to use With our advanced sensors, the Stage II delivers optimal efficiency. Hand wheels provide simple adjustments, enable quick set-up and easy changeover. Easy to maintain In strict compliance with Good Manufacturing Practices (GMP) standards the Stage II is made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments. Additionally, its simplistic design enables quick fixes and easy adjustments. Given this durability and easy maintenance, the Stage II affords you a solid choice in labeling machine longevity. Flexibility- The Stage II’s standard one-button teach product and label sensors can be effortlessly adjusted for various labeling applications. And, with the manual position setting, your labels are placed accurately on the product, each and every time.

- It’s easy to upgrade the Stage II to activate hot-foil printer controls. This integrated feature simplifies label customization and allows the hot-foil printer to work in sync with the labeler to ensure accurate code placement.

- Thanks to the user-friendly operating interface, changing to different labeling applications for various product sizes and types can be done simply and quickly.

- The Stage II’s stepper motor essentially counts the “steps” necessary to reach the next label, ensuring fast, accurate label delivery.

- The Stage II’s controls are fully synchronized, ensuring that all components run at the same speed.

- A production preset function means the machine automatically stops once the predetermined quantity of products has been labeled.

- The label count feature lets you precisely track progress at any point during the production run.

- The container/production run counter lets you see the exact production number for the day.

- The Stage II features a battery-free microprocessor control system that maintains default settings and memory even after the machine sits idle for a long period of time. Up to five settings can be stored for future use, so you don’t have to waste time re-entering the necessary information.

- The Stage II can be easily and conveniently moved to other production areas, allowing for changes in production or products.

- The Stage II is easy to work on and to adjust, putting everything you need at your fingertips with the removal of just a few screws.

- The Stage II is made of 304 stainless steel and anodized aluminum. This extremely durable metal is specially treated to guard against rusting and other effects from harsher environments.

- The Stage II is manufactured in compliance with Good Manufacturing Practices (GMP) standards and meet the strict ISO 9001 quality control procedures. So, you can have confidence undergoing required quarterly inspections from industry compliance auditors.

Label Type- Wrap Around

- Maximum Dispensing Speed : 52.5’/minute, (16m/minute), 60 cont/minute

- Maximum Conveyor Speed : 32.8’/minute, (10m/minute), 60 cont/minute

- Dimensions L-W-H : 43.3” x 34.3” x 20” (1100mm x 870mm x 508mm)

- Maximum Label Size : 4.75” x 11.8” (120mm x 300mm)

- Maximum Container Width : 6.3” (152.4mm)

- Conveyor Width : 6” (152.4mm)

- Spool Diameter : 10” (254mm)

- Inner Core : 3” (76mm)

- Voltage : 110/220 VAC 50/60 HZ 1 Phase

- Power in KW : .460

- Drive : 2 Phase Stepper Motor

- Net Weight : Approx 165 lbs (75 kgs)

-

The Stage III is designed to apply pressure-sensitive labels to round or square bottles. And with just a tap of its one-touch screen, you can easily adjust the settings to apply labels to one side of flat-surfaced containers. The machine’s speed adjusts according to your container’s surface, as well. Model PL-501 Specifications: Simple to use Machine adjustments and changeovers are quick and simple, thanks to the Stage III’s easy-to-operate features. The built-in operating instructions, memory preset and troubleshooting guide offered on the operator interface make it easy to use the Stage III. Hand wheels provide for simple adjustments, enable quick set-up and easy changeover. Easy to maintain The Stage III is made of 304 stainless steel and anodized aluminum and carefully treated to guard against the effects of harsher environments. This durability translates into a solid choice for labeling machine longevity. In strict compliance with Good Manufacturing Practices (GMP) standards, the Stage III is dependable, reliable and easy to maintain.Flexibility

The Stage III is designed to apply pressure-sensitive labels to round or square bottles. And with just a tap of its one-touch screen, you can easily adjust the settings to apply labels to one side of flat-surfaced containers. The machine’s speed adjusts according to your container’s surface, as well. Model PL-501 Specifications: Simple to use Machine adjustments and changeovers are quick and simple, thanks to the Stage III’s easy-to-operate features. The built-in operating instructions, memory preset and troubleshooting guide offered on the operator interface make it easy to use the Stage III. Hand wheels provide for simple adjustments, enable quick set-up and easy changeover. Easy to maintain The Stage III is made of 304 stainless steel and anodized aluminum and carefully treated to guard against the effects of harsher environments. This durability translates into a solid choice for labeling machine longevity. In strict compliance with Good Manufacturing Practices (GMP) standards, the Stage III is dependable, reliable and easy to maintain.Flexibility- With the Stage III, labeling for a diverse range of container sizes is fast and easy. The standard one-touch screen and label sensors make it simple to adjust for various labeling applications. And, with the manual position setting, your labels are placed accurately on the product, each and every time.

- Future upgrades are simple. Thanks to the Stage III’s thermal or hot foil printer controls, you can easily incorporate a printer if the label customization you can turn on or off.

- The auto label-set feature confirms label sensitivity by detecting the separation between each label. With one push of a button, labeling is set up – and positioned correctly.

- The missing label-detect feature locates missing labels on the roll stock, and instantly shuts off the machine if one is found. This preventative feature ensures each product is labeled appropriately.

- The Stage III’s controls are fully synchronized, ensuring that all components run at the same speed.

- By essentially counting the “steps” necessary to reach the next label, the Stage III’s stepper motors ensure fast, accurate label delivery.

- A production preset function means the machine automatically stops once the predetermined quantity of products has been labeled.

- The label count feature lets you precisely track progress at any point during the production run.

- The container/production run counter lets you see the exact production number for the day.

- The Stage III features a touchscreen control system with job memory. So, even after the machine sits idle for long periods, you benefit from a battery-free microprocessor control system that stores default settings. Up to 30 settings can be stored for future use, so you don’t have to waste time re-entering the necessary information.

- The Stage III can be easily and conveniently moved to other production areas, allowing for changes in production or products.

- The height of the machine’s conveyor is adjustable, affording you exceptional convenience and flexibility.

- The Stage III labeler is made of 304 stainless steel and anodized aluminum. This extremely durable metal is specially treated to guard against rusting and other effects from harsher environments.

Label Types- Wrap Around, One Side Apply Optional

- Maximum Dispensing Speed : 131.2’/min (40m/min)

- Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

- Dimensions L-W-H : 79” x 40” x 41” (2006mm x 1016mm x 1041mm)

- Maximum Label Size : 6” x 11.8” (152mm x 300mm)

- Maximum Container Width : 4” (101mm) *6” (152mm) Optional

- Conveyor Width : 3.25” (82.55mm)

- Conveyor Height : 31.75-47.75” (806-1213mm)

- Spool Diameter : 14” (356mm)

- Inner Core : 3” (76mm)

- Voltage : 110/220 VAC 50/60 HZ 1 Phase

- Power in KW : .700

- Drive : Stepper Motor

- Approx 330 lbs (150 kgs)

- Delta Color Touch Screen

-

Piston Filler Specifications: Principal Features:

Piston Filler Specifications: Principal Features:- Standard with Airtac Piston.

- All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

- Viscous Liquid Model with stainless steel product hopper

- Operated by foot pedal switcher or by automatic timer.

- With Anti-leaking system

- Product suction and dispensing speed adjustable.

- No-Tools for set-up and adjustment.

- Sanitary tri-clamp connections easy wash

- Quick release nozzle and feed pipe

- Small footprint for simple bench mounting

- Be able to be equipped with other automatic packaging machine

- Festo Piston

- Food and pharmaceutical S/S 316 grade stainless steel contact parts.

- For some viscous liquid, the mixing & heating hopper is option.

-

Standard with electrical solenoid controls, we have as an option, a pneumatic solenoid valve that works without electrical, that is fully pneumatic driven.

- Air Consumption: 0.6CBM/H

- Air Supply Pressure: 0.4-0.6Mpa

- Operation Efficiency: 10-20 bottles per min (depends on product and container size)

- Filling Precision: ≦±1%

- Dimension & Weight: Variable, depending on the application

-

Model 40 Citrus Juicer Specifications:

Model 40 Citrus Juicer Specifications:- Power supply: 110--120V 60HZ

- Power consumption: 370W

- Size of orange required: 40--90mm

- Output: 40-60 oranges/3 liters/0.8 gallon/minute

- Machine Size: 540L x 610W x 1750H mm (length x width x height)

- Weight: 92kg

- Security: Safety cut out switches

- the machines will not working without the cover place

- Plastic Transparent Face Cover

- 304 Stainless Steel Housing

- Juicing Kit (standard): 8 cavity

-

Liquifier Design The Liquifier is designed to dissolve solids or semi-solids where time, temperature and complete hydration are important. Originally developed to dissolve natural gums and synthetic thickeners used in the manufacture of frozen desserts, the Liquifier dissolves and disperses virtually any food product more efficiently and completely than any other system available. The unit will put into solution, not just suspension, products that can be dissolved by agitation. The benefits of the Liquifier include dissolving soluble products in less than 5 minutes, complete hydration, total product liquifaction, elimination of solid "burn-on" in the vat, elimination of waste at strainers and tank bottoms and the complete disbursement of insoluble particles in water or non-aqueous media. The Emulsifying and Blending System Materials: All of the contact parts are made of SS316L (Outer shell SS304) 200L emulsifying tank Scrape agitation 3-Stage Emulsifying Pump Pipe system Output: 0.5-3T/H Millstone Diameter: 120mm Cooling water pipe: 12mm Outlet Diameter: 32mm Inlet Diameter: 66mm Speed: 2800rpm Sharp power: 7.5 KW UL or CE rated motor (220V/60HZ,3Phase) Medium: Nuts or Smoothies Includes all piping, valves and fittings necessary to complete the system

Liquifier Design The Liquifier is designed to dissolve solids or semi-solids where time, temperature and complete hydration are important. Originally developed to dissolve natural gums and synthetic thickeners used in the manufacture of frozen desserts, the Liquifier dissolves and disperses virtually any food product more efficiently and completely than any other system available. The unit will put into solution, not just suspension, products that can be dissolved by agitation. The benefits of the Liquifier include dissolving soluble products in less than 5 minutes, complete hydration, total product liquifaction, elimination of solid "burn-on" in the vat, elimination of waste at strainers and tank bottoms and the complete disbursement of insoluble particles in water or non-aqueous media. The Emulsifying and Blending System Materials: All of the contact parts are made of SS316L (Outer shell SS304) 200L emulsifying tank Scrape agitation 3-Stage Emulsifying Pump Pipe system Output: 0.5-3T/H Millstone Diameter: 120mm Cooling water pipe: 12mm Outlet Diameter: 32mm Inlet Diameter: 66mm Speed: 2800rpm Sharp power: 7.5 KW UL or CE rated motor (220V/60HZ,3Phase) Medium: Nuts or Smoothies Includes all piping, valves and fittings necessary to complete the system