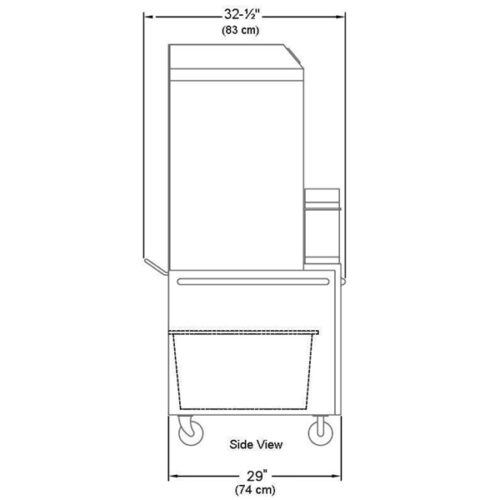

The Model 100 is our standard juice press. Big on production, yet small enough to fit through a standard doorway; it is perfect for Juice Bars, Health-food Stores, Storefront Operations, low volume Juice Bottling, and more.

Specifications:

- Juice Rate: 20-40Gallons per Hour (75-150 Liters per Hour)

- Electrical: 20A, 200-240VAC, 1ɸ (Single Phase)

- L6-20P Plug and Cord

- 9" Shredder Blade(s)

- Shredder Speed: 0-3600 RPM

- Net Weight: 535lb (243kg)

- All Stainless Hardware and Lines

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- No Feed Tube/No Shredding

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- Shredder System w/Interlock

- Juice Collection Pan(s)

- Two (2) Press Bags (Model 200: 4)

- Perforated Press Board(s)

- Three (3) Shredder Blade Sizes

- Produce Plunger

- Tool Set w/ Spare hardware

- Limited Warranty

- I have a used one for $6,000, sold as is