|

|

| Minimum Size Product Accepted: 5 Micron | |

| Maximum Mesh Size: Variable up to 500 | |

| Output: 5-10 kg/minute | |

| Motor Certification: CE | |

| Power: 1.5kw | |

| Diameter: 1200mm | |

| Automatic sediment removal |

-

Model 40 Citrus Juicer Specifications:

Model 40 Citrus Juicer Specifications:- Power supply: 110--120V 60HZ

- Power consumption: 370W

- Size of orange required: 40--90mm

- Output: 40-60 oranges/3 liters/0.8 gallon/minute

- Machine Size: 540L x 610W x 1750H mm (length x width x height)

- Weight: 92kg

- Security: Safety cut out switches

- the machines will not working without the cover place

- Plastic Transparent Face Cover

- 304 Stainless Steel Housing

- Juicing Kit (standard): 8 cavity

-

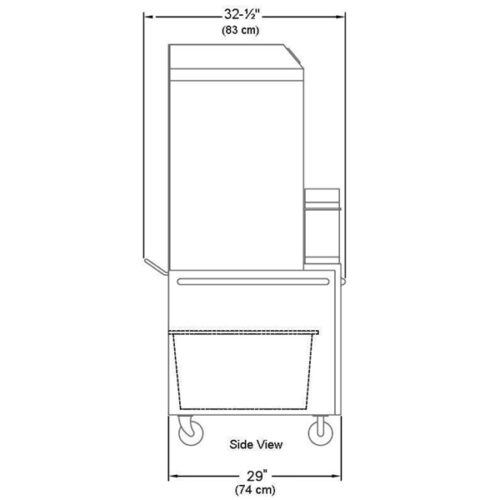

Model Multi-Fruit Juicer Specifications:

Model Multi-Fruit Juicer Specifications:- Throughput: 20 fruit per minute

- Fruit Hopper Capacity: 40 lbs. (18 kg) – 1 carton

- Processing Speed: 80-120 quarts (76-114 liters) per hour

- Reservoir Capacity: 3-1/2 gallons (13 liters)

- Height: 67" (170 cm)

- Width 27" (69 cm)

- Depth 32" (81 cm)

- Height: 73" (186 cm)

- Width 30" (76 cm)

- Depth 36" (91 cm)

- 115 volts

- 60 Hz

- 20 amps service

- Single phase

- 110/220 volts...

- 50/60 Hz

- 20/10 amps service...

- single phase

- Completely enclosed, safety interlock switches

- Finish High impact, flame retardant ABS or stainless steel (optional)

- Weight: 535 lbs. (243 kg)...

- Shipping Wt.: 570 lbs. (259 kg)

- Waste Container Holds: 40 lbs. (18 kg)

- Average Fruit Size: 2-1/2" (63.5 mm) to 3-7/8" (98 mm)

- Orange Count: Per 40 lb. (18 kg) Carton...48 to 138

- Grapefruit Count: Per 40 lb. (18 kg) Carton...48 to 56

- Lemons, Limes Count: Per 40 lb. (18 kg) Carton...95 to 200

- Versatility: Juices all types of citrus fruit without adjustment

- Optional: Strainer tubes for various juice pulp requirements

- High quality juice with minimal peel oil

- Reliable, easy to operate and safe equipment that processes a wide range of types and sizes of citrus

- fruits

- A juicer that achieves the highest juice yields from all fruits – at a reasonable speed

- Sweet tasting, freshly squeezed juice

- made daily

- Good value for the price

- Nothing but juice – no seeds, no peel

- To see the juicing process in action

- A sanitary design to ensure product quality and shelf life

-

The Z450 and Z450P models have been designed to obtain top quality fresh juices from whole fruits from the most unique technology available. The machine is able to squeeze all types of citric fruit- oranges, lemon, limes, tangerines and grapefruits as well as the Z450P being able to process pomegranates on top of the citric capabilities. The juice extractor is pre-assembled and factory tested before delivery for quick and easy installation. Model Z-450 Specifications: Juicing Kit (standard): 8 cavity intermediate Kit Production: 400¸450 litres/hour Diameter of Fruit: Min. Ø70 mm; max. Ø85 mm Optional - 7 Cavity : min. Ø85 mm; max. Ø100 mm - 9 Cavity : min. Ø60 mm; max. Ø70 mm Weight: 400 Kg (approximate) Measurements (h x l x w): 2.2 x 2.5 x 1 (metres) Consumption: 2,01 kW Voltage: 220V / 60 Hz.

The Z450 and Z450P models have been designed to obtain top quality fresh juices from whole fruits from the most unique technology available. The machine is able to squeeze all types of citric fruit- oranges, lemon, limes, tangerines and grapefruits as well as the Z450P being able to process pomegranates on top of the citric capabilities. The juice extractor is pre-assembled and factory tested before delivery for quick and easy installation. Model Z-450 Specifications: Juicing Kit (standard): 8 cavity intermediate Kit Production: 400¸450 litres/hour Diameter of Fruit: Min. Ø70 mm; max. Ø85 mm Optional - 7 Cavity : min. Ø85 mm; max. Ø100 mm - 9 Cavity : min. Ø60 mm; max. Ø70 mm Weight: 400 Kg (approximate) Measurements (h x l x w): 2.2 x 2.5 x 1 (metres) Consumption: 2,01 kW Voltage: 220V / 60 Hz. -

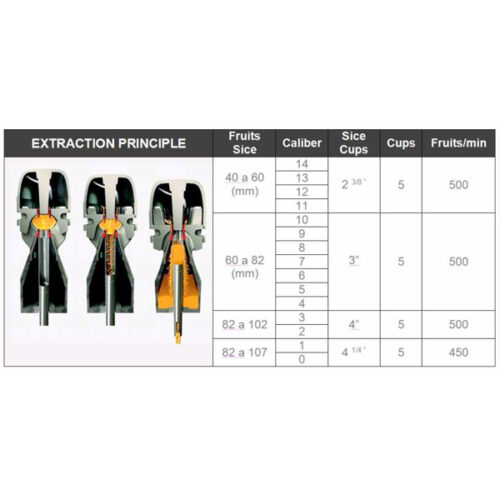

Model PGE Specifications:

Model PGE Specifications:- Production: 500 Fruits/min.

- Yield: from 48% to 52% (according to variety of fruit).

- Approximate weight: 1.700 kgs.

- Consumption: 15.5 Kw/hour.

- Voltage: Three-phase 220V / 50-60 Hz. // 380V / 50-60 Hz.

- Water: 5.28 - 6.6 Gal/min to 4 bar (316.8 - 396 Gal/hour to 59º F).

- Air compressed: For instrumentation to 6 bar.

-

100-500 Liter Tank Specifications:

100-500 Liter Tank Specifications:- Material: All of the contact parts are made of SS316 stainless, the rest 304 stainless

- Size: 100-500 Liters

- Agitation: Scrape Agitation

- Power: 220V/60HZ/3 Phase UL certified motors included

- Motor Covers: Stainless

- Piping: Stainless Steel Piping, valves, and fittings included, when system is ordered

-

Piston Filler Specifications: Principal Features:

Piston Filler Specifications: Principal Features:- Standard with Airtac Piston.

- All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

- Viscous Liquid Model with stainless steel product hopper

- Operated by foot pedal switcher or by automatic timer.

- With Anti-leaking system

- Product suction and dispensing speed adjustable.

- No-Tools for set-up and adjustment.

- Sanitary tri-clamp connections easy wash

- Quick release nozzle and feed pipe

- Small footprint for simple bench mounting

- Be able to be equipped with other automatic packaging machine

- Festo Piston

- Food and pharmaceutical S/S 316 grade stainless steel contact parts.

- For some viscous liquid, the mixing & heating hopper is option.

-

Standard with electrical solenoid controls, we have as an option, a pneumatic solenoid valve that works without electrical, that is fully pneumatic driven.

- Air Consumption: 0.6CBM/H

- Air Supply Pressure: 0.4-0.6Mpa

- Operation Efficiency: 10-20 bottles per min (depends on product and container size)

- Filling Precision: ≦±1%

- Dimension & Weight: Variable, depending on the application

-

The Stage II semi-automatic overflow filler is a logical next step for a medium size cold press juice facility. You can chose from 4, all the way up to 8 heads filling juice at one time. It is ideal for a fast-growing company to bottle their juices at an economical price. Model Specifications:

The Stage II semi-automatic overflow filler is a logical next step for a medium size cold press juice facility. You can chose from 4, all the way up to 8 heads filling juice at one time. It is ideal for a fast-growing company to bottle their juices at an economical price. Model Specifications:- Simple Design

- 4 to 8 Liquid Filling Nozzles

- 316 Stainless Steel Contact Parts are Standard

- Heavy-duty 2 inch bore air cylinder with mechanical stroke adjustment

- 5.5 Gallon stainless steel overflow tank

- 4 ports hose 304 stainless steel feeding manifold

- Fill Glass, Tin, Plastic Containers

- All contact parts are stainless steel, sanitary, Teflon, Viton, Buna, and hoses per your requirements

- Calibrated guide for fast height changeovers

- Leveling of the machine by 16mm 304 stainless steel leveling screws

- 13 Gallons per minute diaphragm pump

- Height nozzles can be fully adjustable

- Container height adjustment from 1.5 to 12 inches high

- No change parts needed for various types of containers

- Air filter regulator and safety lockout valve included

- 10 cfm@80psi

-

The Stage III automatic in-line overflow filler is for companies that are doing a larger production, wanting to cut labor costs and at a very economical price. It is ideal for a larger commissary or juice plant, as it can fill different varieties of bottles quickly. Model A-12 Specifications:

The Stage III automatic in-line overflow filler is for companies that are doing a larger production, wanting to cut labor costs and at a very economical price. It is ideal for a larger commissary or juice plant, as it can fill different varieties of bottles quickly. Model A-12 Specifications:- All Stainless Steel Frame

- Stainless Steel Conveyor, 12 Ft. or Longer with Adjustable Guide Rails

- Electronic/Pneumatic Timing and Counting System

- Drip Tray

- EZ Clean Manifold

- Handle From 1/2 Pint To One Gallon Containers

- Air Cylinders, Bottle Gates, Sensors & Timers Control All Movements

- Stainless Steel Centrifugal Pump

- Totally Enclosed Motor with Variable Speed Drives

- Solid State PLC Control with Color Touch Screen

- 316 Stainless Steel Contact Parts Are Standard

- Nema 4x Enclosures

-

The Model 200 is our starter unit for the next step up. Two press zones and a moveable Shredder System act together to greatly increase juice production. Produces as much juice as competing 6 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and high-volume operations. Specifications: Juice Rate: 40-100Gallons per Hour* (150-370 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 770lb (350kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:

The Model 200 is our starter unit for the next step up. Two press zones and a moveable Shredder System act together to greatly increase juice production. Produces as much juice as competing 6 layer presses! Designed for Commercial Kitchens, Commissaries, Juice Bottling, Cider production, and high-volume operations. Specifications: Juice Rate: 40-100Gallons per Hour* (150-370 Liters per Hour) Electrical: 20A, 200-240VAC, 1ɸ (Single Phase) L6-20P Plug and Cord 9” Shredder Blade(s) Shredder Speed: 0-3600 RPM Net Weight: 770lb (350kg) *Depends greatly on produce. Standard Feature List: Sanitary Features:- All Stainless Steel and Electropolished Construction

- Stainless Hardware and Lines

- Minimized Harborage

- 100% Wash-Down

- Food-Grade Hydraulic Oil

- Two (2) Emergency Stops

- No Feed Tube/No Shredding

- Complete Safety Guarding

- Motor Overload Protection

- Electrical Disconnect

- Warning Labels

- Easy-to-use Control Panel

- Shredder System w/Interlock

- Juice Collection Pan(s)

- Two (2) Press Bags

- Perforated Press Board(s)

- Three (3) Shredder Blade Sizes

- Produce Plunger

- Tool Set w/ Spare hardware

- Limited Warranty